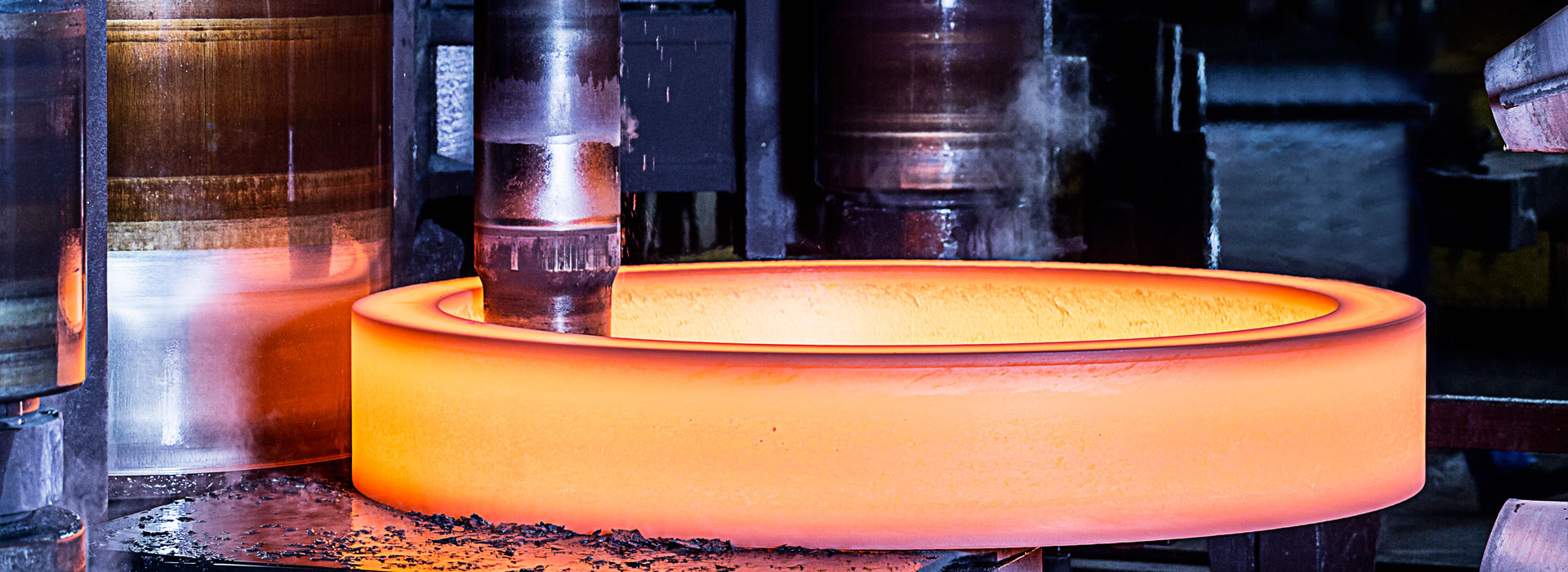

Apa precision forging?

2022-05-17

Precision forgings biasane diproses dening die forging (diarani minangka nggoleki forgings) ing umum utawa khusus die forging peralatan forging dhuwur tliti saka sethitik, ora nglereni proses forging anyar. Mangkono, ngganti cara tempa tradisional lan entuk tujuan nyimpen bahan, nambah produktivitas tanduran tempa lan ningkatake kahanan kerja.

Precision forging fitur proses, forgings nggoleki bisa dipérang dadi suhu kamar, medium lan suhu dhuwur forging miturut suhu beda billet deformed.

Fine forging kudu diwilang billet, ing wektu sing padha kualitas nglereni lan presisi syarat dhuwur. Amarga forging tertutup, kurang lan ora ana cara pemanasan oksidasi kudu diadopsi. Billet saka suhu kamar forging kudu softened (annealed) sadurunge forging.

Precision forging die biasane nggunakake kombinasi forging die, lan wis forging (forging awal) lan precision forging (final forging) rong langkah lan loro dipakani mati, precision forging (final forging) luwih dhuwur tinimbang forging loro.

Amarga penempaan presisi nduweni kaluwihan sing signifikan kanggo ngirit logam lan bisa nyuda wektu nglereni, kayata tempa gear bevel lurus lan gear heliks kanthi untu, ora perlu dipotong sawise ditempa, lan bagean awak blade presisi blade ora perlu. dipotong maneh.

Precision forging fitur proses, forgings nggoleki bisa dipérang dadi suhu kamar, medium lan suhu dhuwur forging miturut suhu beda billet deformed.

Fine forging kudu diwilang billet, ing wektu sing padha kualitas nglereni lan presisi syarat dhuwur. Amarga forging tertutup, kurang lan ora ana cara pemanasan oksidasi kudu diadopsi. Billet saka suhu kamar forging kudu softened (annealed) sadurunge forging.

Precision forging die biasane nggunakake kombinasi forging die, lan wis forging (forging awal) lan precision forging (final forging) rong langkah lan loro dipakani mati, precision forging (final forging) luwih dhuwur tinimbang forging loro.

Amarga penempaan presisi nduweni kaluwihan sing signifikan kanggo ngirit logam lan bisa nyuda wektu nglereni, kayata tempa gear bevel lurus lan gear heliks kanthi untu, ora perlu dipotong sawise ditempa, lan bagean awak blade presisi blade ora perlu. dipotong maneh.

Minangka precision forging nguatake kabeh pranala sing relevan ing proses die forging, biaya tambah. Mulane, forging presisi umume digunakake kanggo bagean sing angel dipotong utawa laborious, uga forgings karo syarat sing luwih dhuwur ing kinerja, kayata gir, rodha cacing, glathi bengkong lan bagean aviation.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy