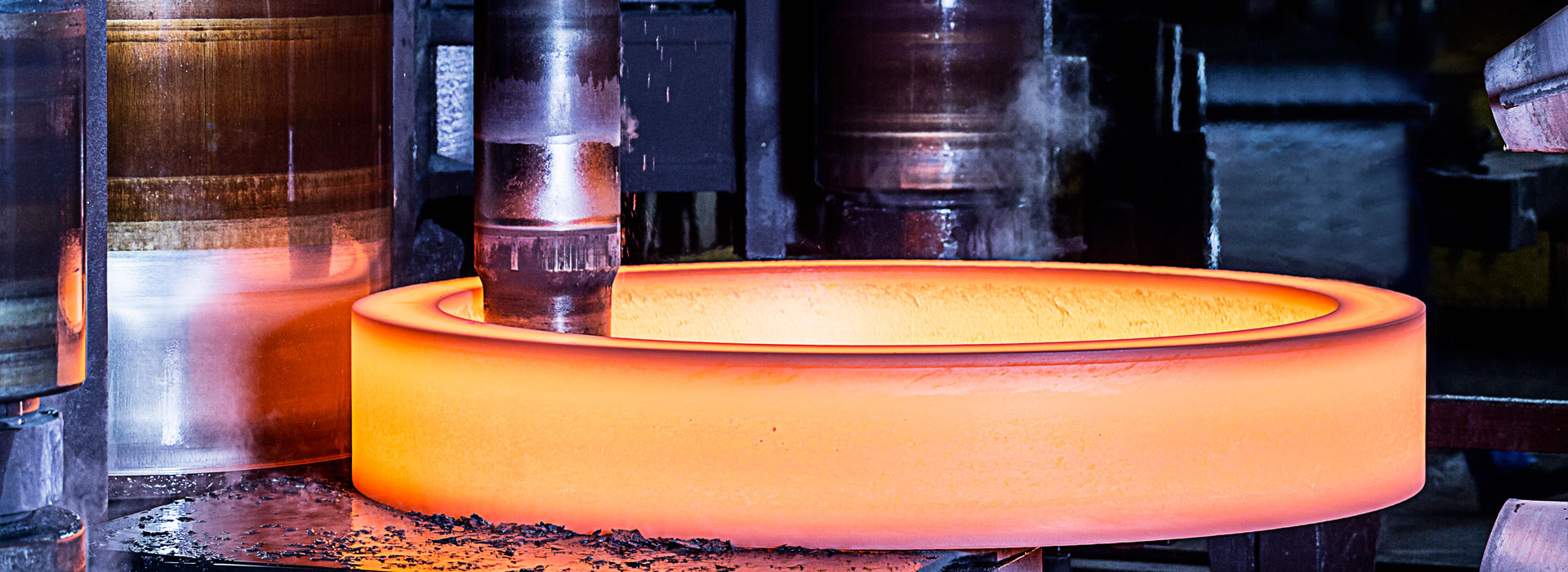

Apa sing kedadeyan sajrone perawatan panas saka forgings?

2022-05-25

Sajrone perawatan panas saka forgings, volume massa struktur beda beda, supaya volume massa forgings bound kanggo ngganti. Amarga ana prabédan suhu antarane lumahing lan jantung forging, lumahing lan jantung transformasi organisasi ora pas wektune, supaya owah-owahan volume massa internal lan eksternal bakal gawé kaku internal. Tekanan internal sing disebabake dening heterogenitas transformasi organisasi diarani stres transisi fase.

Volume massa saka struktur dhasar baja mundhak ing urutan austenite, pearlite, sortenite, troosite, bainit ngisor, martensite tempered lan martensite. Contone, forgings quenching cooling cepet, amarga lumahing kadhemen pisanan kanggo kang titik, supaya lumahing saka austenite menyang martensite, volume swell, nanging jantung isih ing negara austenite, nyegah swell lumahing, supaya jantung forging dening tensile kaku, lumahing dening kaku compressive; Nalika terus kelangan, suhu lumahing suda lan ora bakal swell maneh, nalika inti bakal terus swell amarga transformasi menyang martensite, supaya bakal dicegah dening lumahing.

Dadi jantung kena tekanan kompresif, lan permukaan kena tekanan tarik. Kaku iki tetep ing forging sawise cooling minangka kaku residual.

Mulane, ing proses cooling quenching, owah-owahan kaku termal lan kaku owah-owahan phase ngelawan, lan kaku ampas final ing forging uga ngelawan. Tekanan gabungan stres termal lan stres owah-owahan fase,

Volume massa saka struktur dhasar baja mundhak ing urutan austenite, pearlite, sortenite, troosite, bainit ngisor, martensite tempered lan martensite. Contone, forgings quenching cooling cepet, amarga lumahing kadhemen pisanan kanggo kang titik, supaya lumahing saka austenite menyang martensite, volume swell, nanging jantung isih ing negara austenite, nyegah swell lumahing, supaya jantung forging dening tensile kaku, lumahing dening kaku compressive; Nalika terus kelangan, suhu lumahing suda lan ora bakal swell maneh, nalika inti bakal terus swell amarga transformasi menyang martensite, supaya bakal dicegah dening lumahing.

Dadi jantung kena tekanan kompresif, lan permukaan kena tekanan tarik. Kaku iki tetep ing forging sawise cooling minangka kaku residual.

Mulane, ing proses cooling quenching, owah-owahan kaku termal lan kaku owah-owahan phase ngelawan, lan kaku ampas final ing forging uga ngelawan. Tekanan gabungan stres termal lan stres owah-owahan fase,

Iki diarani quenching internal stress. Nalika kaku internal ampas ing forging ngluwihi titik ngasilaken saka baja, workpiece bakal gawé deformasi plastik, asil ing distorsi saka forging.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy