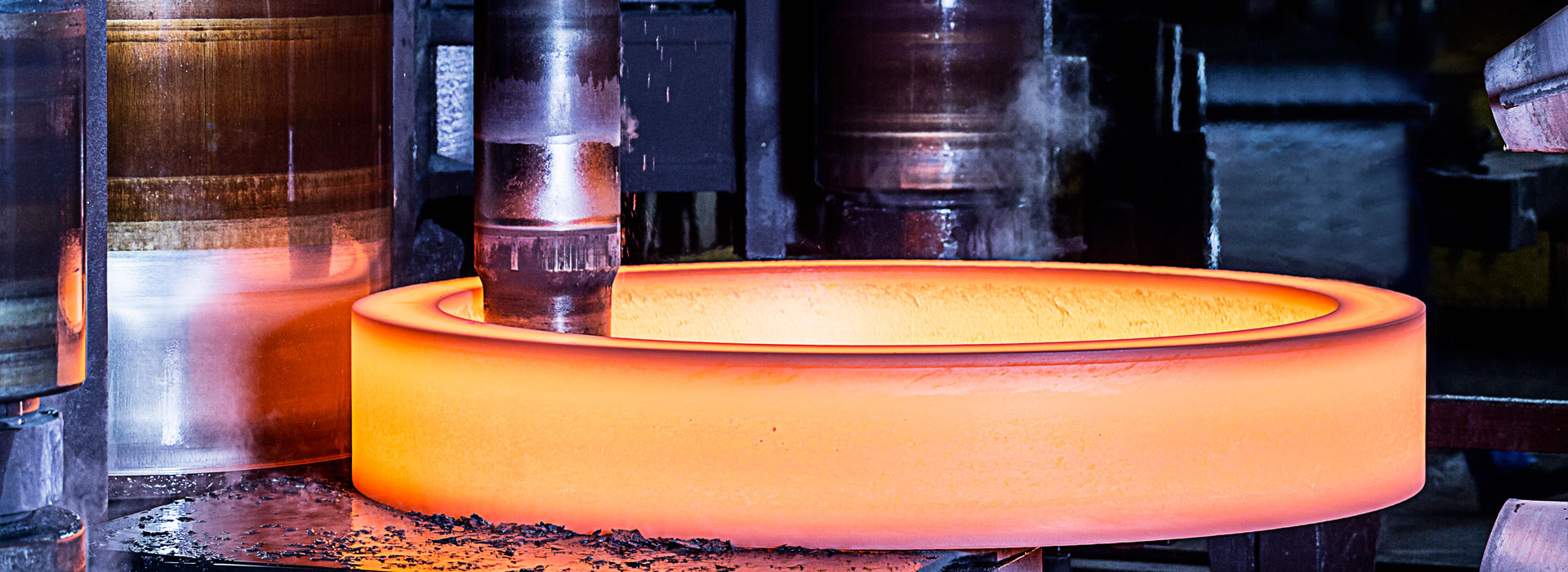

Metode perawatan panas limbah kanggo karya tempa

2022-07-11

Ana papat cara perawatan umum saka forging panas sampah ing karya forging: forging sampah panas quenching, forging sampah panas tempering, forging sampah normalizing lan forging sampah panas annealing.

Sampah panas quenching sakapenempaan:

Proses forging mrodhuksi ewah-ewahan bentuk, mburi forging, miturut materi beda wis cooling utawa isothermal kanggo suhu kita kudu sawise cara cooling nggunakake banyu utawa lenga cooling cepet, forgings njaluk quenching martensite adhedhasar organisasi, punika sampah. panas quenching.

Forging waste heat conditioning:

Pabrik Forgings bakal forgings menyang pawon kanggo panas kanggo suhu forging, sawise pengawetan panas kanggo forging, sawise mburi forging, miturut materi beda wis cooling utawa isothermal kanggo suhu quenching kita kudu, pilih medium quenching cocog kanggo cooling quenching, kanggo njupuk martensite quenching adhedhasar struktur. Banjur kita temperake ing suhu dhuwur kanggo entuk sifat mekanik sing dibutuhake. Dibandhingake karo conventional quenching lan tempering, sampah panas quenching lan tempering saka forgings bisa nambah kekuatan tensile, kekuatan ngasilaken, impact lemes resistance, plasticity lan fraktur kateguhan, lan ngurangi emosi brittleness lan biaya saka baja struktural alloy.

Forging waste heat normalizing:

Proses forging mrodhuksi ewah-ewahan bentuk, pungkasan forging pungkasan, miturut bahan beda wis cooling utawa isothermal kanggo suhu kita kudu milih ing cooling online, soxaustenite adhedhasar organisasi, punika sampah normalizing panas.

Limbah panas annealing kanggo forging:

Sampah panas quenching sakapenempaan:

Proses forging mrodhuksi ewah-ewahan bentuk, mburi forging, miturut materi beda wis cooling utawa isothermal kanggo suhu kita kudu sawise cara cooling nggunakake banyu utawa lenga cooling cepet, forgings njaluk quenching martensite adhedhasar organisasi, punika sampah. panas quenching.

Forging waste heat conditioning:

Pabrik Forgings bakal forgings menyang pawon kanggo panas kanggo suhu forging, sawise pengawetan panas kanggo forging, sawise mburi forging, miturut materi beda wis cooling utawa isothermal kanggo suhu quenching kita kudu, pilih medium quenching cocog kanggo cooling quenching, kanggo njupuk martensite quenching adhedhasar struktur. Banjur kita temperake ing suhu dhuwur kanggo entuk sifat mekanik sing dibutuhake. Dibandhingake karo conventional quenching lan tempering, sampah panas quenching lan tempering saka forgings bisa nambah kekuatan tensile, kekuatan ngasilaken, impact lemes resistance, plasticity lan fraktur kateguhan, lan ngurangi emosi brittleness lan biaya saka baja struktural alloy.

Forging waste heat normalizing:

Proses forging mrodhuksi ewah-ewahan bentuk, pungkasan forging pungkasan, miturut bahan beda wis cooling utawa isothermal kanggo suhu kita kudu milih ing cooling online, soxaustenite adhedhasar organisasi, punika sampah normalizing panas.

Limbah panas annealing kanggo forging:

Proses forging mrodhuksi ewah-ewahan bentuk, mburi forging, miturut macem-macem bahan wis cooling utawa isothermal kanggo suhu kita kudu milih ing pawon utawa cooling cooling alon cooling, njaluk ing matriks ferrite mbagekke ing flake utawa bundher carbide- organisasi adhedhasar, punika sampah panas annealing.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy