Karakteristik proses produksi tempa

2022-07-15

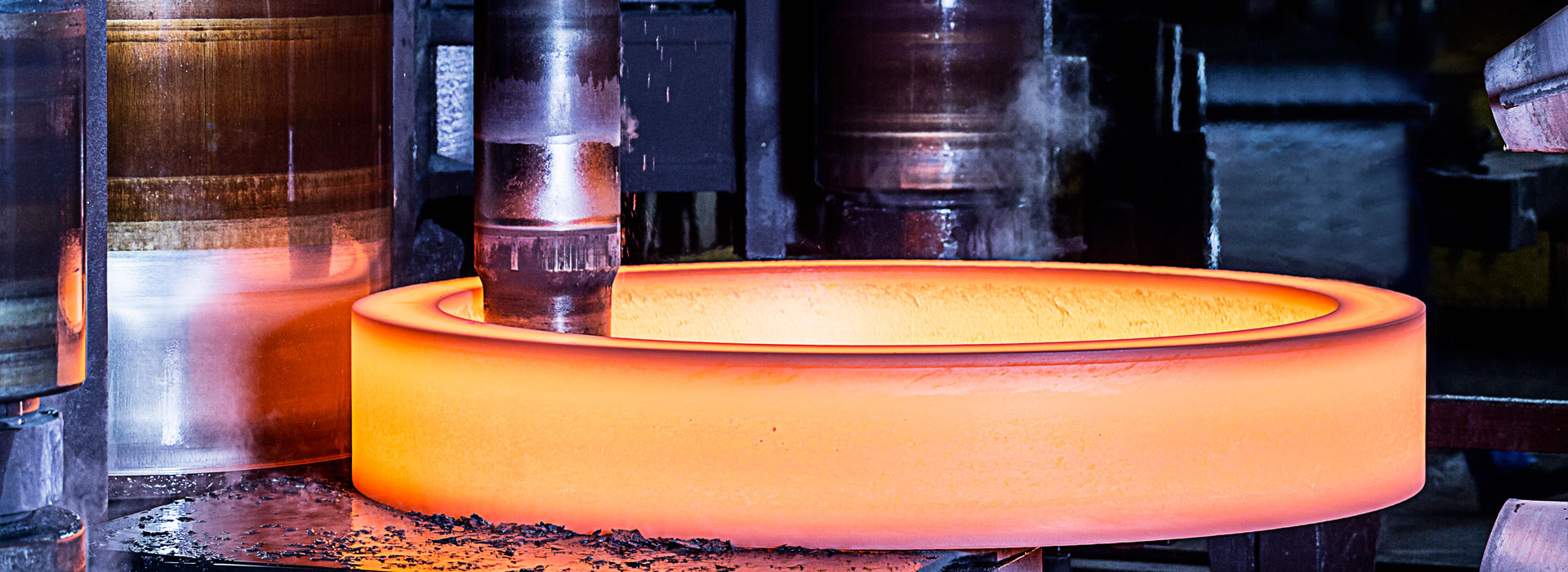

Forgingssing nyetak menyang struktur logam dibutuhake dening forging, kang bisa nambah sifat logam (ngencengi struktur internal). Forgings biasane sawise forging panas, cast asli ngeculke, pori-pori, mikro-retak lan ing compacted, kristal dendritik baja bejat, supaya pari-parian dadi nggoleki. Ing wektu sing padha, pemisahan karbida asli lan distribusi sing ora rata diganti kanggo nggawe seragam mikro. Forgings ditondoi dening forging internal kandhel, seragam, nggoleki, kinerja lengkap apik, nggunakake forgings dipercaya (workpiece).

Proses produksi forgings kanggo nggawe aliran plastik logam lan nggawe wangun sing dibutuhake saka workpiece. Volume logam tetep sawise aliran plastik disebabake pasukan njaba, lan logam tansah mili menyang bagean karo resistance cilik. Ing forging, wangun forgings asring dikontrol miturut aturan kasebut, lan wangun kasar saka forgings dipalsukan dening upsetting, drawing, reaming, mlengkung, drawing lan cara deformasi liyane. Gedhe kumpulan forgings kanggo nggawe ukuran akurat, kondusif kanggo organisasi produksi massal, bisa Applied kanggo cara jamur mbentuk, organisasi produksi massa profesional utawa produksi massal.

Proses produksi forgings kanggo nggawe aliran plastik logam lan nggawe wangun sing dibutuhake saka workpiece. Volume logam tetep sawise aliran plastik disebabake pasukan njaba, lan logam tansah mili menyang bagean karo resistance cilik. Ing forging, wangun forgings asring dikontrol miturut aturan kasebut, lan wangun kasar saka forgings dipalsukan dening upsetting, drawing, reaming, mlengkung, drawing lan cara deformasi liyane. Gedhe kumpulan forgings kanggo nggawe ukuran akurat, kondusif kanggo organisasi produksi massal, bisa Applied kanggo cara jamur mbentuk, organisasi produksi massa profesional utawa produksi massal.

Proses penempaan kalebu blanking, pemanasan lan pretreatment sadurunge dibentuk. Sawise mbentuk, forgings diproses dening lathe kanggo ngethok wates, lan sifat-sifat forgings sing apik liwat perawatan panas. Sawise rampung nglereni, wangun forgings nyukupi syarat gambar. Sawise perawatan permukaan lan kemasan, bisa dikirim.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy