Apa sifat tempa?

2022-11-16

Forgingsing forging umume kudu liwat forging, nglereni, perawatan panas lan pangolahan liyane. Supaya kanggo mesthekake kualitas Manufaktur mati lan ngurangi biaya produksi, materi kudu malleability apik, machinability, hardenability, hardenability lan grindability; Sampeyan uga kudu duwe oksidasi cilik, sensitivitas dekarbonisasi lan deformasi quenching lan cenderung retak.

1. Malleability: Wis kurang panas forging resistance ewah-ewahan bentuk, plasticity apik, sudhut forging sawetara suhu, kurang forging kadhemen cracking lan udan karbida jaringan.

2. Teknologi Annealing: sawetara suhu annealing spheroidization amba, atose annealing kurang lan sawetara fluktuasi cilik, tingkat spheroidization dhuwur.

3. Machinability: jumlah nglereni gedhe, mundhut alat kurang, roughness lumahing mesin kurang.

4. Oksidasi lan sensitivitas decarbonization: Nalika dadi panas ing suhu dhuwur, antioksidan bisa apik, kacepetan decarbonization alon, medium panas ora sensitif, lan cenderung pitting cilik.

5, hardening: sawise quenching karo atose lumahing seragam lan dhuwur.

6. Hardenability: lapisan quenching luwih jero bisa dipikolehi sawise quenching, lan nggunakake medium quenching Moderate bisa hardened.

7, quenching ewah-ewahan bentuk lan retak cenderung: pangowahan volume quenching conventional cilik, wangun warping, distorsi iku tipis, cenderung ewah-ewahan bentuk abnormal kurang. Sensitivitas retak quenching konvensional kurang lan ora sensitif marang suhu quenching lan wangun workpiece.

1. Malleability: Wis kurang panas forging resistance ewah-ewahan bentuk, plasticity apik, sudhut forging sawetara suhu, kurang forging kadhemen cracking lan udan karbida jaringan.

2. Teknologi Annealing: sawetara suhu annealing spheroidization amba, atose annealing kurang lan sawetara fluktuasi cilik, tingkat spheroidization dhuwur.

3. Machinability: jumlah nglereni gedhe, mundhut alat kurang, roughness lumahing mesin kurang.

4. Oksidasi lan sensitivitas decarbonization: Nalika dadi panas ing suhu dhuwur, antioksidan bisa apik, kacepetan decarbonization alon, medium panas ora sensitif, lan cenderung pitting cilik.

5, hardening: sawise quenching karo atose lumahing seragam lan dhuwur.

6. Hardenability: lapisan quenching luwih jero bisa dipikolehi sawise quenching, lan nggunakake medium quenching Moderate bisa hardened.

7, quenching ewah-ewahan bentuk lan retak cenderung: pangowahan volume quenching conventional cilik, wangun warping, distorsi iku tipis, cenderung ewah-ewahan bentuk abnormal kurang. Sensitivitas retak quenching konvensional kurang lan ora sensitif marang suhu quenching lan wangun workpiece.

8. Grindability: Mundhut relatif saka setir mecah cilik, ora watesan diobong jumlah mecah gedhe, iku ora sensitif kualitas mecah wheel lan kahanan cooling, lan iku ora gampang kanggo tlatah lan tlatah retak.

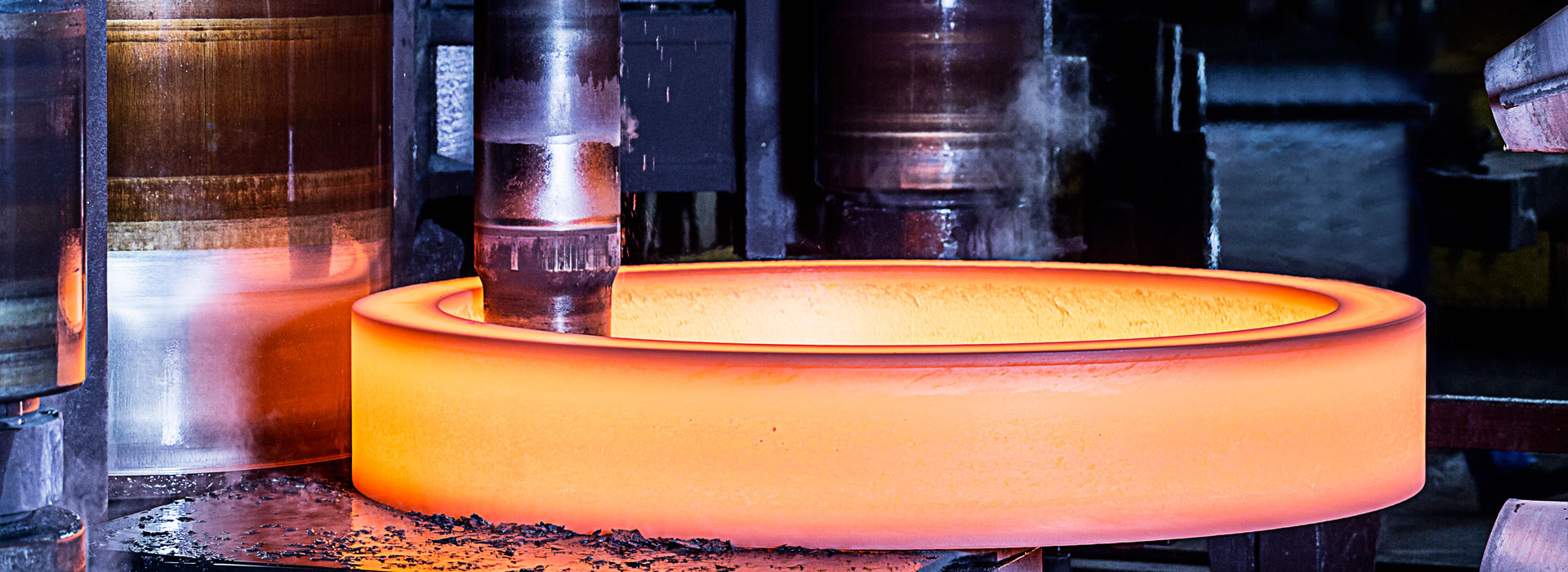

barang kita siap dikirim menyang pelanggan sing seneng-

iki gambar nyata kiriman saka tongxin precision forging

Sadurunge:Pitu cara umum kanggo ngolah pangolahan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy