Klasifikasi Forging

2022-02-23

Kategori Palsu

Miturut suhu forging, bisa dipérang dadi panas forging, panas forging lan kadhemen forging.

Miturut mekanisme mbentuk, forging bisa dipérang dadi free forging, die forging, ring rolling lan forging khusus.

1. Free forging. Iku nuduhake cara Processing forgings sing nggunakake alat universal prasaja utawa langsung aplikasi pasukan external kanggo kothong antarane anvils ndhuwur lan ngisor saka peralatan forging kanggo deform kothong kanggo diwenehi wangun geometris dibutuhake lan kualitas internal. Forgings diprodhuksi dening cara free forging disebut free forgings. Free forging utamané adhedhasar produksi kelompok cilik saka forgings. Peralatan tempa kayata palu tempa lan tekanan hidrolik digunakake kanggo mbentuk lan ngolah kosong kanggo entuk tempa sing mumpuni. Proses dhasar saka forging gratis kalebu upsetting, drawing, punching, cutting, mlengkung, torsion, offset lan forging. Free forging kabeh hot forging.

2. Die forging. Die forging dipérang dadi open die forging lan ditutup die forging. Kothong logam dikompres lan deformed ing rongga die forging kanthi wangun tartamtu kanggo entuk penempaan. Die forging umume digunakake kanggo ngasilake bagean kanthi bobot cilik lan batch gedhe.

Die forging bisa dipérang dadi panas forging, warm forging lan cold forging. Forging anget lan penempaan kadhemen minangka arah pangembangan mangsa penempaan, lan uga makili tingkat teknologi penempaan. Miturut materi, die forging uga bisa dipérang dadi ferrous metal die forging, non-ferrous metal die forging lan bubuk produk mbentuk. Minangka jeneng kasebut, bahan kasebut minangka logam ferrous kayata baja karbon, logam non-ferrous kayata tembaga lan aluminium, lan bahan metalurgi bubuk. Extrusion kudu dadi die forging, sing bisa dipérang dadi extrusion logam abot lan ekstrusi logam ringan. Perlu dicathet yen kosong ora bisa diwatesi kanthi lengkap. Kanggo alasan iki, volume kosong kudu dikontrol kanthi ketat, posisi relatif saka die forging kudu dikontrol lan tempa kudu diukur, lan upaya kudu ditindakake kanggo nyuda nyandhang die forging.

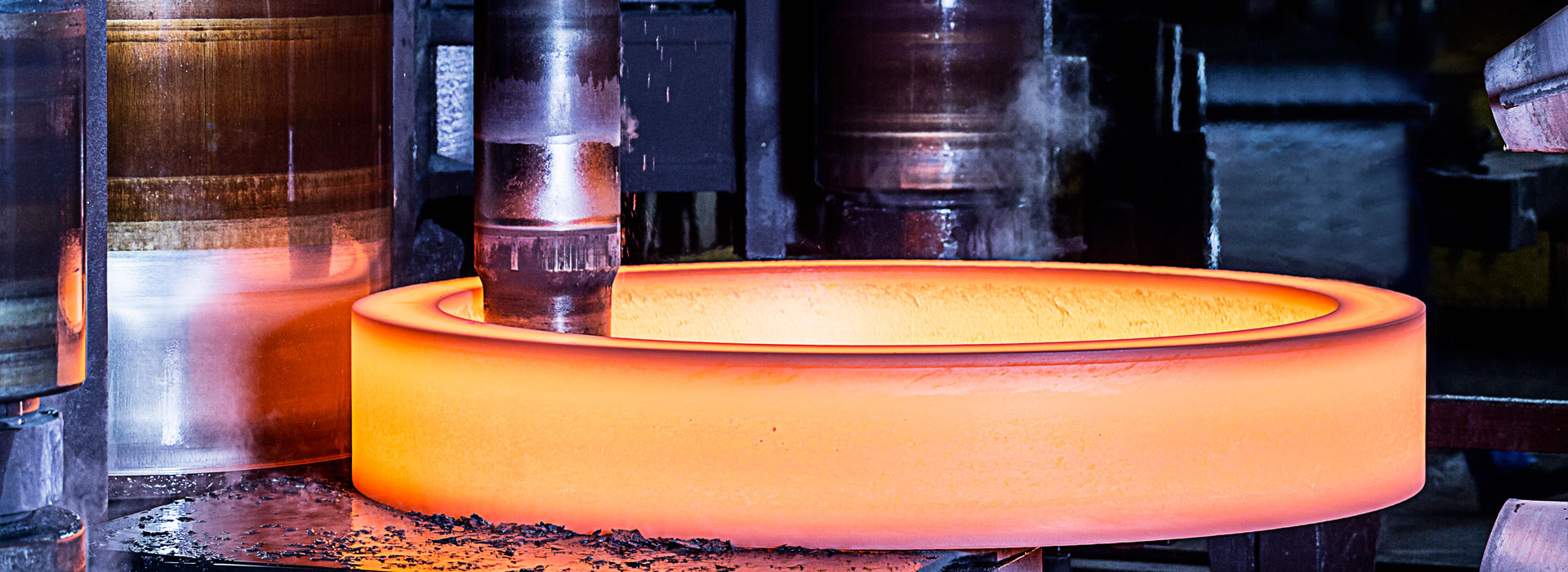

3, rolling ring. Ring rolling nuduhake produksi bagean ring-shaped diameteripun beda liwat peralatan khusus mesin ring-mecah, lan uga digunakake kanggo gawé bagean wheel-shaped kayata hub mobil lan gembong Sepur.

4. Tempa khusus. Forging khusus kalebu roll forging, cross wedge rolling, radial forging, liquid die forging lan cara forging liyane, sing luwih cocok kanggo produksi bagean kanthi bentuk khusus.

Miturut suhu forging, bisa dipérang dadi panas forging, panas forging lan kadhemen forging.

Miturut mekanisme mbentuk, forging bisa dipérang dadi free forging, die forging, ring rolling lan forging khusus.

1. Free forging. Iku nuduhake cara Processing forgings sing nggunakake alat universal prasaja utawa langsung aplikasi pasukan external kanggo kothong antarane anvils ndhuwur lan ngisor saka peralatan forging kanggo deform kothong kanggo diwenehi wangun geometris dibutuhake lan kualitas internal. Forgings diprodhuksi dening cara free forging disebut free forgings. Free forging utamané adhedhasar produksi kelompok cilik saka forgings. Peralatan tempa kayata palu tempa lan tekanan hidrolik digunakake kanggo mbentuk lan ngolah kosong kanggo entuk tempa sing mumpuni. Proses dhasar saka forging gratis kalebu upsetting, drawing, punching, cutting, mlengkung, torsion, offset lan forging. Free forging kabeh hot forging.

2. Die forging. Die forging dipérang dadi open die forging lan ditutup die forging. Kothong logam dikompres lan deformed ing rongga die forging kanthi wangun tartamtu kanggo entuk penempaan. Die forging umume digunakake kanggo ngasilake bagean kanthi bobot cilik lan batch gedhe.

Die forging bisa dipérang dadi panas forging, warm forging lan cold forging. Forging anget lan penempaan kadhemen minangka arah pangembangan mangsa penempaan, lan uga makili tingkat teknologi penempaan. Miturut materi, die forging uga bisa dipérang dadi ferrous metal die forging, non-ferrous metal die forging lan bubuk produk mbentuk. Minangka jeneng kasebut, bahan kasebut minangka logam ferrous kayata baja karbon, logam non-ferrous kayata tembaga lan aluminium, lan bahan metalurgi bubuk. Extrusion kudu dadi die forging, sing bisa dipérang dadi extrusion logam abot lan ekstrusi logam ringan. Perlu dicathet yen kosong ora bisa diwatesi kanthi lengkap. Kanggo alasan iki, volume kosong kudu dikontrol kanthi ketat, posisi relatif saka die forging kudu dikontrol lan tempa kudu diukur, lan upaya kudu ditindakake kanggo nyuda nyandhang die forging.

3, rolling ring. Ring rolling nuduhake produksi bagean ring-shaped diameteripun beda liwat peralatan khusus mesin ring-mecah, lan uga digunakake kanggo gawé bagean wheel-shaped kayata hub mobil lan gembong Sepur.

4. Tempa khusus. Forging khusus kalebu roll forging, cross wedge rolling, radial forging, liquid die forging lan cara forging liyane, sing luwih cocok kanggo produksi bagean kanthi bentuk khusus.

Contone, roll forging bisa digunakake minangka proses preforming efektif kanggo nemen nyuda meksa mbentuk sakteruse; salib wedge rolling bisa gawé bagean kayata bal baja lan drive shafts; forging radial bisa gawé forgings gedhe kayata tong minyak lan stepped shafts

Sadurunge:Precision Auto Parts - Sajarah Forgings

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy