Carane njaga kualitas forging blanks?

2022-12-13

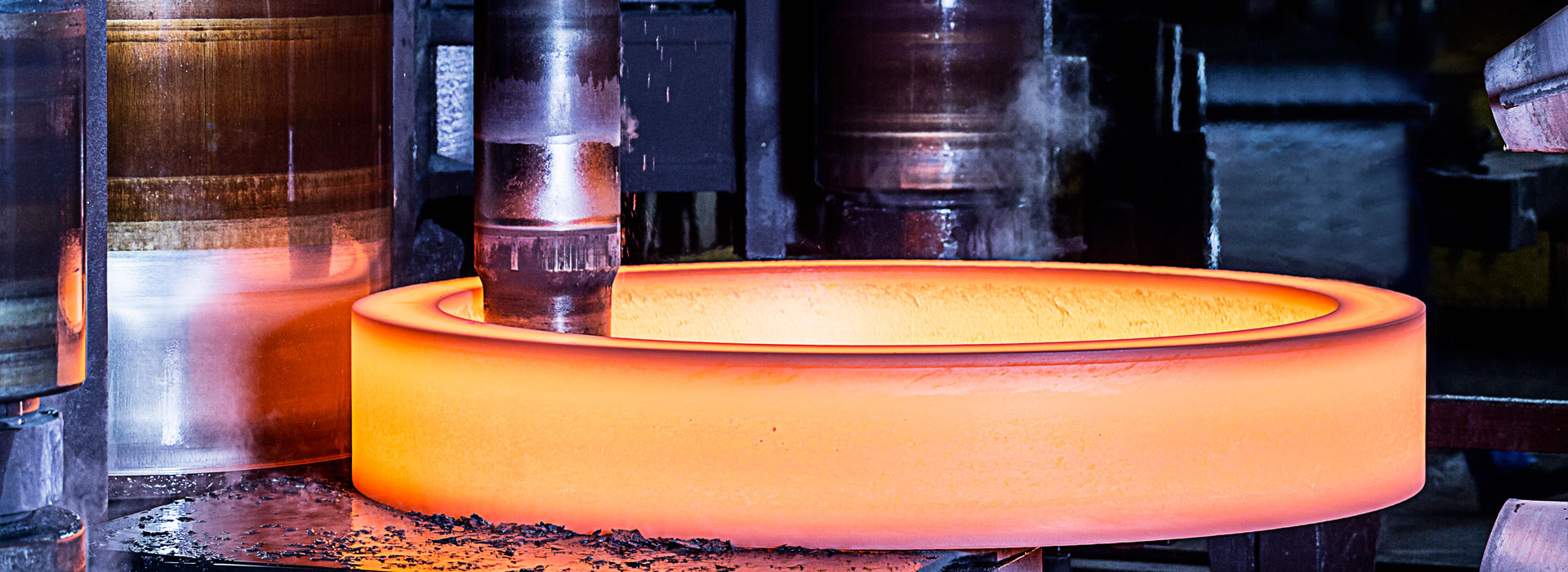

Carane njaga kualitas forging blanks?

Saiki, akeh model manca sing dienalake ing pabrik mobil China lan kahanan teknis bahan gear wis ditemtokake karo standar sing cocog. Keperluan khusus kanggo hardenability stabil baja H (baja karburisasi karbon rendah karbon rendah) wis nyebabake perhatian sing akeh dening pabrik baja lan departemen sing cocog. Dipercaya yen sawise sawetara wektu, liwat transformasi teknis pabrik baja lan nggunakake teknologi sing apik, kualitas bahan tempa kothong bakal tambah akeh. Nalika iku, ditambah karo adopsi teknologi sing apik dening industri mobil, kualitas peralatan mobil uga bakal saya apik.

Sawise anil isothermal gearpenempaankosong (nuduhake baja carburized alloy umum, kanggo sawetara baja carburized alloy dhuwur, annealing isothermal uga angel kanggo nyegah tatanan bainite, perlu kanggo nambah proses tempering suhu dhuwur) ora mung kanggo mesthekake kinerja nglereni banget, nanging uga amarga entuk organisasi seragam, stabilitas dimensi sawise quenching carburizing uga bantuan gedhe. Mesthi, kanggo nggawe pindah ing proses carburizing quenching ewah-ewahan bentuk cilik lan stabil, nanging uga perlu materi hardenability dhewe bisa stabil, bagean diselehake roto-roto ing piring ngisor kanggo mesthekake uniformity saka quenching cooling, lan proses cooling saka pilihan saka cooling lenga, suhu lenga, aduk kontrol kakiyatan.

Nalika kothong iki dimuat menyang pawon, bobot saben bagean padha kanggo mesthekake kondisi cooling padha. Liwat perawatan iki bisa ngindhari struktur Strip, entuk struktur campuran ferrite - pearlite, kekerasan 140 ~ 170HIB, mesthekake kinerja pemotongan sing apik, bagian permukaan rampung apik, umur alat luwih suwe.

Saiki, akeh model manca sing dienalake ing pabrik mobil China lan kahanan teknis bahan gear wis ditemtokake karo standar sing cocog. Keperluan khusus kanggo hardenability stabil baja H (baja karburisasi karbon rendah karbon rendah) wis nyebabake perhatian sing akeh dening pabrik baja lan departemen sing cocog. Dipercaya yen sawise sawetara wektu, liwat transformasi teknis pabrik baja lan nggunakake teknologi sing apik, kualitas bahan tempa kothong bakal tambah akeh. Nalika iku, ditambah karo adopsi teknologi sing apik dening industri mobil, kualitas peralatan mobil uga bakal saya apik.

Sawise anil isothermal gearpenempaankosong (nuduhake baja carburized alloy umum, kanggo sawetara baja carburized alloy dhuwur, annealing isothermal uga angel kanggo nyegah tatanan bainite, perlu kanggo nambah proses tempering suhu dhuwur) ora mung kanggo mesthekake kinerja nglereni banget, nanging uga amarga entuk organisasi seragam, stabilitas dimensi sawise quenching carburizing uga bantuan gedhe. Mesthi, kanggo nggawe pindah ing proses carburizing quenching ewah-ewahan bentuk cilik lan stabil, nanging uga perlu materi hardenability dhewe bisa stabil, bagean diselehake roto-roto ing piring ngisor kanggo mesthekake uniformity saka quenching cooling, lan proses cooling saka pilihan saka cooling lenga, suhu lenga, aduk kontrol kakiyatan.

Nalika kothong iki dimuat menyang pawon, bobot saben bagean padha kanggo mesthekake kondisi cooling padha. Liwat perawatan iki bisa ngindhari struktur Strip, entuk struktur campuran ferrite - pearlite, kekerasan 140 ~ 170HIB, mesthekake kinerja pemotongan sing apik, bagian permukaan rampung apik, umur alat luwih suwe.

Sadurunge:Cara kanggo nguji atose bagian palsu

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy