Bahan penempaan

2022-02-24

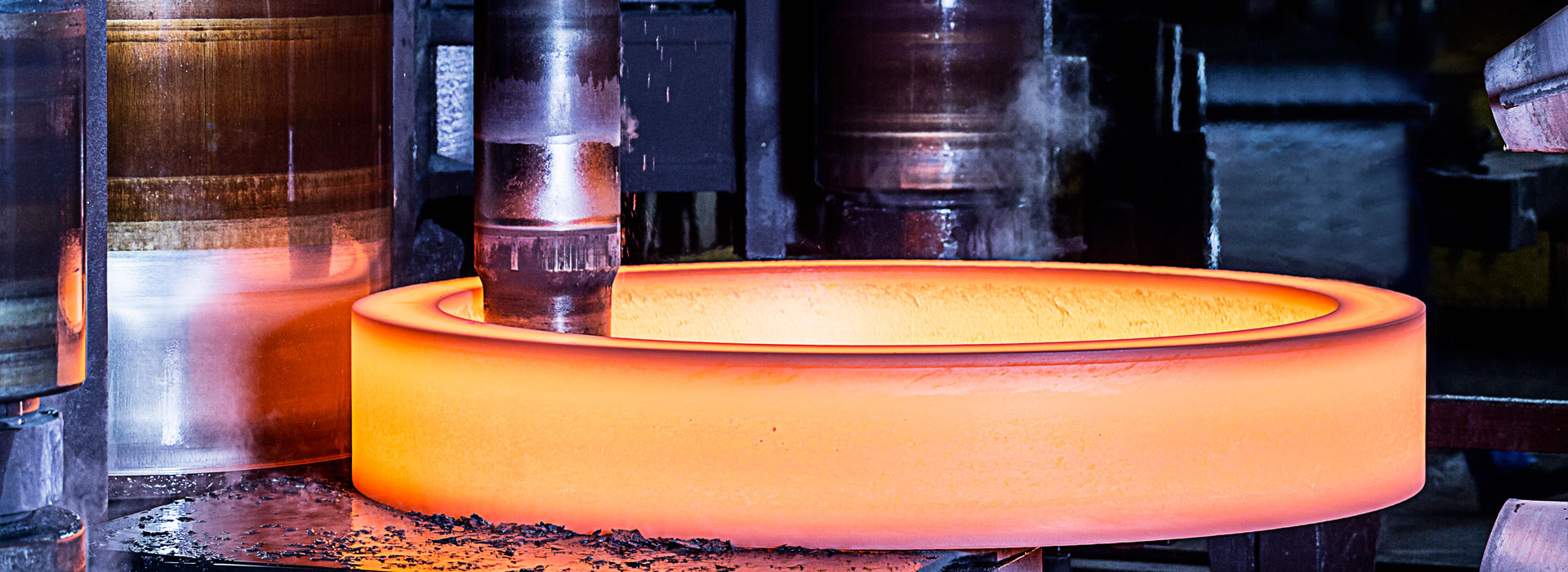

Bahan penempa utamane yaiku baja karbon lan baja paduan saka macem-macem komposisi, diikuti dening aluminium, magnesium, tembaga, titanium, lan sapiturute lan paduane, superalloy basis wesi, superalloys basis nikel, lan superalloys basis kobalt. Wesi cacat uga dipalsukan. Utawa cara rolling wis rampung, nanging wesi iki relatif angel forge amarga zona plastik relatif sempit, lan suhu panas, mbukak suhu forging lan suhu forging final saka bahan beda duwe syarat ketat.

Negara mentahan materi yaiku bar, ingot, bubuk logam lan logam cair. Rasio area cross-sectional logam sadurunge deformasi menyang area cross-sectional sawise deformasi diarani rasio forging.

Negara mentahan materi yaiku bar, ingot, bubuk logam lan logam cair. Rasio area cross-sectional logam sadurunge deformasi menyang area cross-sectional sawise deformasi diarani rasio forging.

Pilihan sing bener saka rasio forging, suhu pemanasan sing cukup lan wektu ditahan, suhu penempaan awal sing cukup lan suhu penempaan pungkasan, jumlah deformasi sing cukup lan kecepatan deformasi duwe akeh hubungane karo ningkatake kualitas produk lan ngurangi biaya.

Sadurunge:Forgings jinis gear

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy