Kaluwihan saka open die forging

2022-02-25

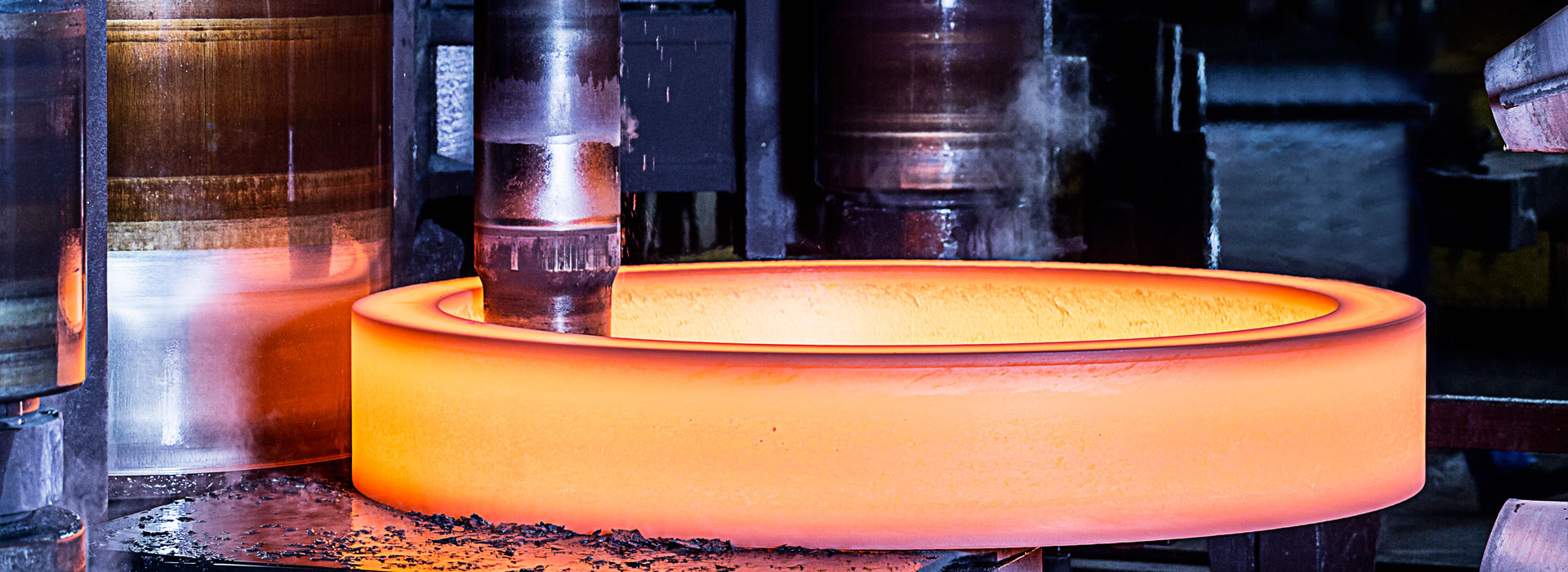

Open die forging nuduhake cara Processing forgings sing nggunakake alat universal prasaja utawa langsung aplikasi pasukan external kanggo kothong antarane anvils ndhuwur lan ngisor saka peralatan forging kanggo deform kothong kanggo diwenehi wangun geometris dibutuhake lan kualitas internal. Forgings diprodhuksi deningOpen die forgingcara disebut free forgings.

Open die forgingutamané adhedhasar produksi kelompok cilik forgings. Peralatan tempa kayata palu tempa lan tekanan hidrolik digunakake kanggo mbentuk lan ngolah kosong kanggo entuk tempa sing mumpuni. Proses dhasar saka forging gratis kalebu upsetting, drawing, punching, cutting, mlengkung, torsion, offset lan forging. Free forging kabeh hot forging.

Ing open die forgingProses penempaan meliputi proses dasar, proses bantu dan proses finishing.

Proses dhasar saka open die forgingforging: upsetting, drawing, punching, mlengkung, nglereni, torsion, nutup kerugian lan forging, etc., lan telung pangolahan sing paling umum digunakake ing produksi nyata upsetting, drawing, lan punching.

Proses tambahan: proses pra-deformasi, kayata mencet rahang, mencet pinggiran ingot baja, nglereni pundak, etc.

Proses Finishing: Proses nyuda cacat lumahing forgings, kayata mbusak unevenness lan mbentuk saka lumahing forgings.

kauntungan:

(1) Great forging keluwesan, bisa gawé bagean cilik kurang saka 100kg, lan uga bisa gawé bagean abot nganti 300t utawa luwih;

(2) Piranti kang digunakake yaiku piranti umum kang prasaja;

(3) Forging mbentuk kanggo mboko sithik deform kothong ing wilayah beda, supaya tonase peralatan forging dibutuhake kanggo forging forging padha luwih cilik tinimbang model forging;

(4) Syarat kanggo akurasi peralatan kurang;

Open die forgingutamané adhedhasar produksi kelompok cilik forgings. Peralatan tempa kayata palu tempa lan tekanan hidrolik digunakake kanggo mbentuk lan ngolah kosong kanggo entuk tempa sing mumpuni. Proses dhasar saka forging gratis kalebu upsetting, drawing, punching, cutting, mlengkung, torsion, offset lan forging. Free forging kabeh hot forging.

Ing open die forgingProses penempaan meliputi proses dasar, proses bantu dan proses finishing.

Proses dhasar saka open die forgingforging: upsetting, drawing, punching, mlengkung, nglereni, torsion, nutup kerugian lan forging, etc., lan telung pangolahan sing paling umum digunakake ing produksi nyata upsetting, drawing, lan punching.

Proses tambahan: proses pra-deformasi, kayata mencet rahang, mencet pinggiran ingot baja, nglereni pundak, etc.

Proses Finishing: Proses nyuda cacat lumahing forgings, kayata mbusak unevenness lan mbentuk saka lumahing forgings.

kauntungan:

(1) Great forging keluwesan, bisa gawé bagean cilik kurang saka 100kg, lan uga bisa gawé bagean abot nganti 300t utawa luwih;

(2) Piranti kang digunakake yaiku piranti umum kang prasaja;

(3) Forging mbentuk kanggo mboko sithik deform kothong ing wilayah beda, supaya tonase peralatan forging dibutuhake kanggo forging forging padha luwih cilik tinimbang model forging;

(4) Syarat kanggo akurasi peralatan kurang;

(5) Siklus produksi cendhak.

Sadurunge:Bahan penempaan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy