Kategori penempaan

Miturut mekanisme mbentuk, forging bisa dipérang dadi gratispenempaan, die forging, grinding ring lan forging khusus

Three Gorges ship lift nut billet

1, free forging. Iku nuduhake cara Processing forging bagean karo pribadi universal prasaja, utawa langsung nglamar pasukan external kanggo kothong antarane anvils ndhuwur lan ngisor saka forging peralatan, supaya kothong bisa deformed lan wangun geometris dibutuhake lan kualitas internal bisa dipikolehi. . Penempaan sing diasilake kanthi metode free forging diarani free forging. Free forging adhedhasar produksi nomer cilik forgings, forging palu, hydraulic press lan peralatan forging liyane kanggo mbentuk Processing kosong, entuk forgings qualified. Proses dhasar saka forging gratis kalebu upsetting, drawing, punching, cutting, mlengkung, twisting, dislokasi lan forging. Free forging iku kabeh hot forging. [2]

2, die forging. Die forging dipérang dadi open die forging lan ditutup die forging. Kothong logam deformed ing meksa ing forging kamar mati wangun tartamtu kanggo njupuk forging ing. Die forging umume digunakake kanggo ngasilake bobot cilik lan bagean batch gedhe. Die forging bisa dipérang dadi hot die forging, warm forging lan cold forging. Forging anget lan penempaan kadhemen minangka arah pangembangan mangsa penempaan lan makili tingkat teknologi penempaan. [3]

Miturut materi, die forging uga bisa dipérang dadi black metal die forging, non-ferrous metal die forging lan produk bubuk mbentuk. Minangka jeneng gawe katut, iku bahan sing baja karbon lan logam ferrous liyane, tembaga lan aluminium lan logam non-ferrous liyane lan bahan metallurgy bubuk.

Extrusion kudu lantaran kanggo die forging, bisa dipérang dadi extrusion logam abot lan extrusion logam entheng.

Lini produksi ekstrusi Yankuang Group 150MN, paling gedhe ing donya

Lini produksi ekstrusi Yankuang Group 150MN, paling gedhe ing donya

Die forging ditutup lan ditutup upsetting forging rong Techniques majeng die forging. Amarga ora ana pinggiran mabur, tingkat panggunaan materi dhuwur. Sampeyan bisa rampung forgings Komplek karo siji utawa luwih langkah. Amarga ora ana pinggiran mabur, wilayah pasukan forgings suda, mbukak dibutuhake suda. Nanging, kudu dicathet yen kothong ora bisa diwatesi kanthi lengkap, mula kudu ngontrol volume kosong, ngontrol posisi relatif saka die forging lan ngukur forgings, lan nyoba nyuda nyandhang saka forging. mati. [3]

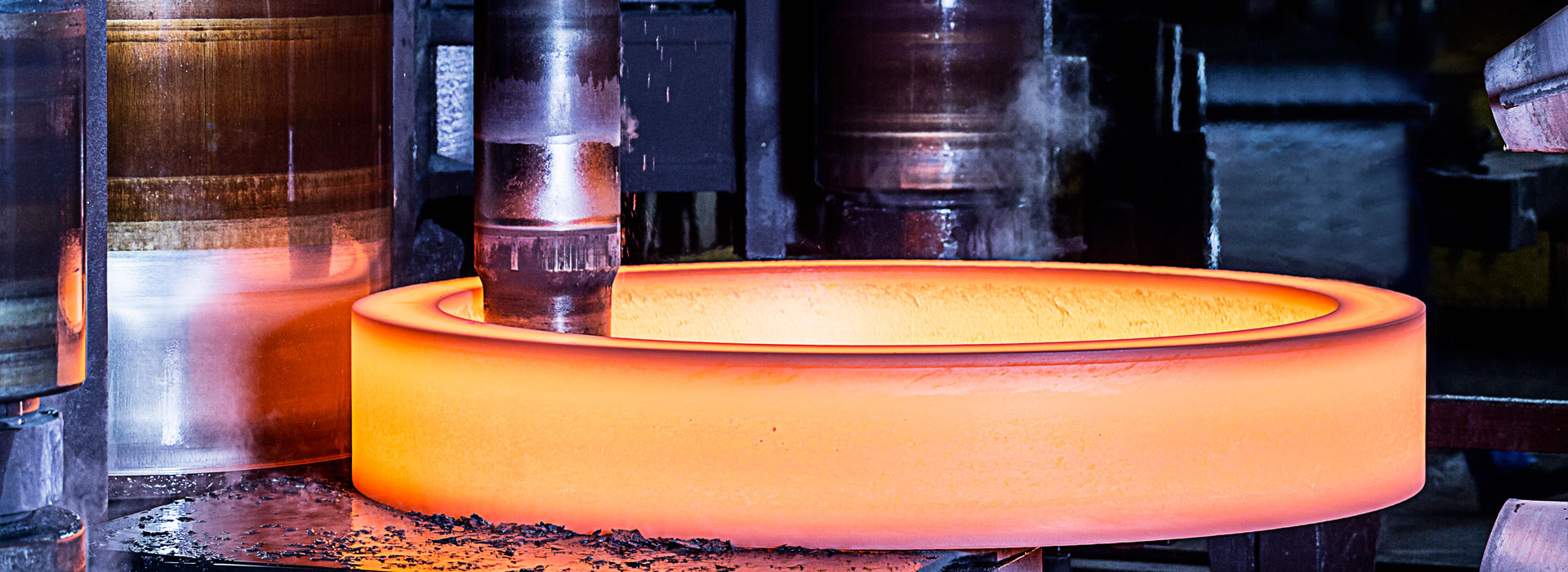

3, mecah ring. Grinding ring nuduhake produksi bagean ring diameteripun beda liwat peralatan khusus mesin ring mecah, uga digunakake kanggo gawé hub wheel mobil, gembong Sepur lan bagean wheel liyane. [4]

4, tempa khusus. Forging khusus kalebu roll forging, cross wedge rolling, radial forging, liquid die forging lan cara forging liyane, sing luwih cocok kanggo produksi sawetara bagean wangun khusus. Contone, roll forging bisa digunakake minangka proses preforming efektif kanggo nemen nyuda meksa mbentuk sakteruse; Rolling wedge salib bisa ngasilake bal baja, poros drive lan bagean liyane; Forging radial bisa ngasilake laras bedhil gedhe, poros langkah lan tempa liyane. [4]

mati

Miturut mode gerakan forging die, forging bisa dipérang dadi swing forging, swing forging, roll forging, cross wedge rolling, ring rolling lan cross rolling. Rotary forging, rotary forging lan rotary penempaan

Pisanan China 400MN (40.000 ton) heavy aviation die forging hydraulic press

Pisanan China 400MN (40.000 ton) heavy aviation die forging hydraulic press

Rings uga bisa machined dening nggoleki forging. Kanggo nambah tingkat panggunaan bahan, roll forging lan cross rolling bisa digunakake minangka proses sadurunge bahan ramping. Rotary forging, kaya free forging, uga sebagian dibentuk. Kauntungane yaiku yen dibandhingake karo ukuran tempa, gaya tempa uga bisa dibentuk ing kahanan cilik. Kalebu forging free, cara forging lan Processing bahan saka lumahing jamur cedhak extension lumahing free, mulane, iku angel kanggo njamin akurasi, supaya bakal arah gerakan saka forging mati lan muter urutan pandhe wesi karo kontrol komputer, pasukan forging ngisor kasedhiya ing wangun Komplek, produk tliti dhuwur, kayata produksi akeh varieties, ukuran gedhe saka forgings agul-agul turbin.

Gerakan die lan tingkat kebebasan nglereni peralatan ora konsisten. Miturut karakteristik watesan deformasi titik mati ngisor, peralatan forging bisa dipérang dadi papat wangun ing ngisor iki:

1, wangun pasukan forging winates: tekanan lenga langsung panggeser hydraulic press.

2. Watesan Quasi-stroke: penet hidrolik sing didorong dening mekanisme crank lan rod penghubung.

3, mode watesan stroke: crank, rod penghubung lan mekanisme wedge kanggo nyopir pers mekanik panggeser.

4. Watesan energi: Meneng lan gesekan penet karo mekanisme meneng.

Tes panas saka penerbangan abot die forging hydraulic press

Tes panas saka penerbangan abot die forging hydraulic press

Three Gorges ship lift nut billet

1, free forging. Iku nuduhake cara Processing forging bagean karo pribadi universal prasaja, utawa langsung nglamar pasukan external kanggo kothong antarane anvils ndhuwur lan ngisor saka forging peralatan, supaya kothong bisa deformed lan wangun geometris dibutuhake lan kualitas internal bisa dipikolehi. . Penempaan sing diasilake kanthi metode free forging diarani free forging. Free forging adhedhasar produksi nomer cilik forgings, forging palu, hydraulic press lan peralatan forging liyane kanggo mbentuk Processing kosong, entuk forgings qualified. Proses dhasar saka forging gratis kalebu upsetting, drawing, punching, cutting, mlengkung, twisting, dislokasi lan forging. Free forging iku kabeh hot forging. [2]

2, die forging. Die forging dipérang dadi open die forging lan ditutup die forging. Kothong logam deformed ing meksa ing forging kamar mati wangun tartamtu kanggo njupuk forging ing. Die forging umume digunakake kanggo ngasilake bobot cilik lan bagean batch gedhe. Die forging bisa dipérang dadi hot die forging, warm forging lan cold forging. Forging anget lan penempaan kadhemen minangka arah pangembangan mangsa penempaan lan makili tingkat teknologi penempaan. [3]

Miturut materi, die forging uga bisa dipérang dadi black metal die forging, non-ferrous metal die forging lan produk bubuk mbentuk. Minangka jeneng gawe katut, iku bahan sing baja karbon lan logam ferrous liyane, tembaga lan aluminium lan logam non-ferrous liyane lan bahan metallurgy bubuk.

Extrusion kudu lantaran kanggo die forging, bisa dipérang dadi extrusion logam abot lan extrusion logam entheng.

Lini produksi ekstrusi Yankuang Group 150MN, paling gedhe ing donya

Lini produksi ekstrusi Yankuang Group 150MN, paling gedhe ing donya

Die forging ditutup lan ditutup upsetting forging rong Techniques majeng die forging. Amarga ora ana pinggiran mabur, tingkat panggunaan materi dhuwur. Sampeyan bisa rampung forgings Komplek karo siji utawa luwih langkah. Amarga ora ana pinggiran mabur, wilayah pasukan forgings suda, mbukak dibutuhake suda. Nanging, kudu dicathet yen kothong ora bisa diwatesi kanthi lengkap, mula kudu ngontrol volume kosong, ngontrol posisi relatif saka die forging lan ngukur forgings, lan nyoba nyuda nyandhang saka forging. mati. [3]

3, mecah ring. Grinding ring nuduhake produksi bagean ring diameteripun beda liwat peralatan khusus mesin ring mecah, uga digunakake kanggo gawé hub wheel mobil, gembong Sepur lan bagean wheel liyane. [4]

4, tempa khusus. Forging khusus kalebu roll forging, cross wedge rolling, radial forging, liquid die forging lan cara forging liyane, sing luwih cocok kanggo produksi sawetara bagean wangun khusus. Contone, roll forging bisa digunakake minangka proses preforming efektif kanggo nemen nyuda meksa mbentuk sakteruse; Rolling wedge salib bisa ngasilake bal baja, poros drive lan bagean liyane; Forging radial bisa ngasilake laras bedhil gedhe, poros langkah lan tempa liyane. [4]

mati

Miturut mode gerakan forging die, forging bisa dipérang dadi swing forging, swing forging, roll forging, cross wedge rolling, ring rolling lan cross rolling. Rotary forging, rotary forging lan rotary penempaan

Pisanan China 400MN (40.000 ton) heavy aviation die forging hydraulic press

Pisanan China 400MN (40.000 ton) heavy aviation die forging hydraulic press

Rings uga bisa machined dening nggoleki forging. Kanggo nambah tingkat panggunaan bahan, roll forging lan cross rolling bisa digunakake minangka proses sadurunge bahan ramping. Rotary forging, kaya free forging, uga sebagian dibentuk. Kauntungane yaiku yen dibandhingake karo ukuran tempa, gaya tempa uga bisa dibentuk ing kahanan cilik. Kalebu forging free, cara forging lan Processing bahan saka lumahing jamur cedhak extension lumahing free, mulane, iku angel kanggo njamin akurasi, supaya bakal arah gerakan saka forging mati lan muter urutan pandhe wesi karo kontrol komputer, pasukan forging ngisor kasedhiya ing wangun Komplek, produk tliti dhuwur, kayata produksi akeh varieties, ukuran gedhe saka forgings agul-agul turbin.

Gerakan die lan tingkat kebebasan nglereni peralatan ora konsisten. Miturut karakteristik watesan deformasi titik mati ngisor, peralatan forging bisa dipérang dadi papat wangun ing ngisor iki:

1, wangun pasukan forging winates: tekanan lenga langsung panggeser hydraulic press.

2. Watesan Quasi-stroke: penet hidrolik sing didorong dening mekanisme crank lan rod penghubung.

3, mode watesan stroke: crank, rod penghubung lan mekanisme wedge kanggo nyopir pers mekanik panggeser.

4. Watesan energi: Meneng lan gesekan penet karo mekanisme meneng.

Tes panas saka penerbangan abot die forging hydraulic press

Tes panas saka penerbangan abot die forging hydraulic press

Supaya diwenehi akurasi dhuwur, care kudu dijupuk kanggo nyegah kakehan ing titik mati ngisor, kacepetan kontrol lan posisi jamur. Amarga iki bakal duwe impact ing forging toleransi, akurasi wangun lan mati urip. Kajaba iku, kanggo njaga akurasi, perhatian uga kudu dibayar kanggo nyetel celah slideway, mesthekake kaku, nyetel titik mati ngisor lan nggunakake piranti transmisi tambahan lan langkah-langkah liyane.

Sadurunge:Pentinge rencana proses forging

Kirim Pitakonan

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy